FAQ - Frequently Asked Questions

Are you selling ATEX (explosion proof) models?

No, unfortunately we do not sell ATEX models.

Can I transport biogas with your normal models anyway? It is not an ignitable mixture.

To ease maintenance, our blowers are not airtight. Therefore an ignitable mixture will be created inside the blower.

According to the experiences of our customers, the mixture is then ignited in the electric motor.

Can your blowers also convey water with the air?

In general, our blowers are designed to transport dry air without dust.

A lot of parts are not intended for humidity.

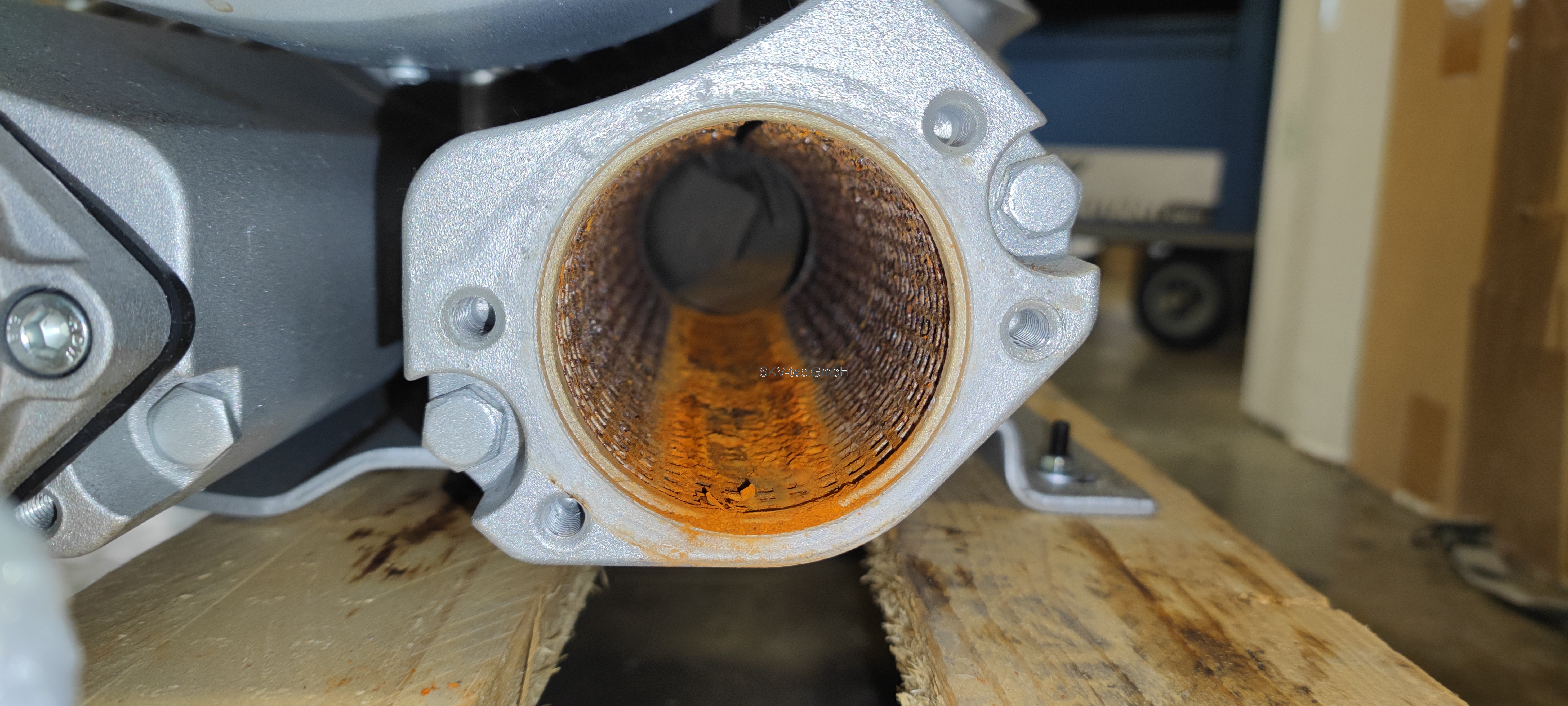

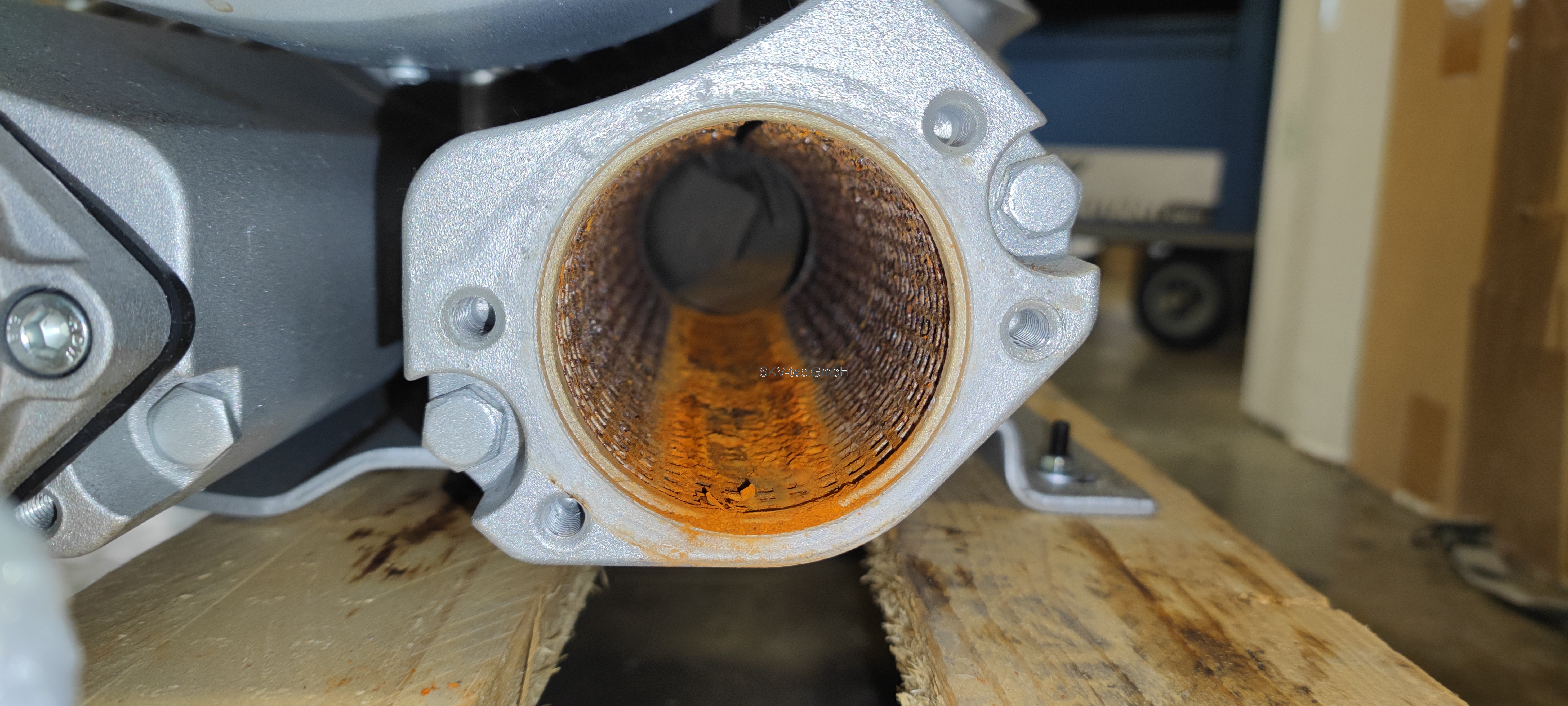

Especially the silencers are destroyed fast by humidity, the bearing on the compressor side will also rust very quickly.

How do you package a blower for parcel delivery? Do we need to repackage goods delivered by truck?

We send out our blowers well padded with paper and still have transport damaged every now and then.

Some series are not sent out as parcels, despite their low weight, if there is no space in the parcel for padding.

Some customers use plastic chips instead of paper for padding.

If the silencers are not covered, this material can enter the blower during transport.

Starting the blower without removing the plastic chips can damage it.

Blowers that are send out without padding are basically guaranteed transport damages.

Where can I find the dimensions sheets?

In general the dimension sheets are part of our data sheets and can be found on page 2.

Link to our data sheets

STP files can be requested by email.

Do I really need filtration? The transported air is clean...

In general, our blowers are only suited to transport clean air.

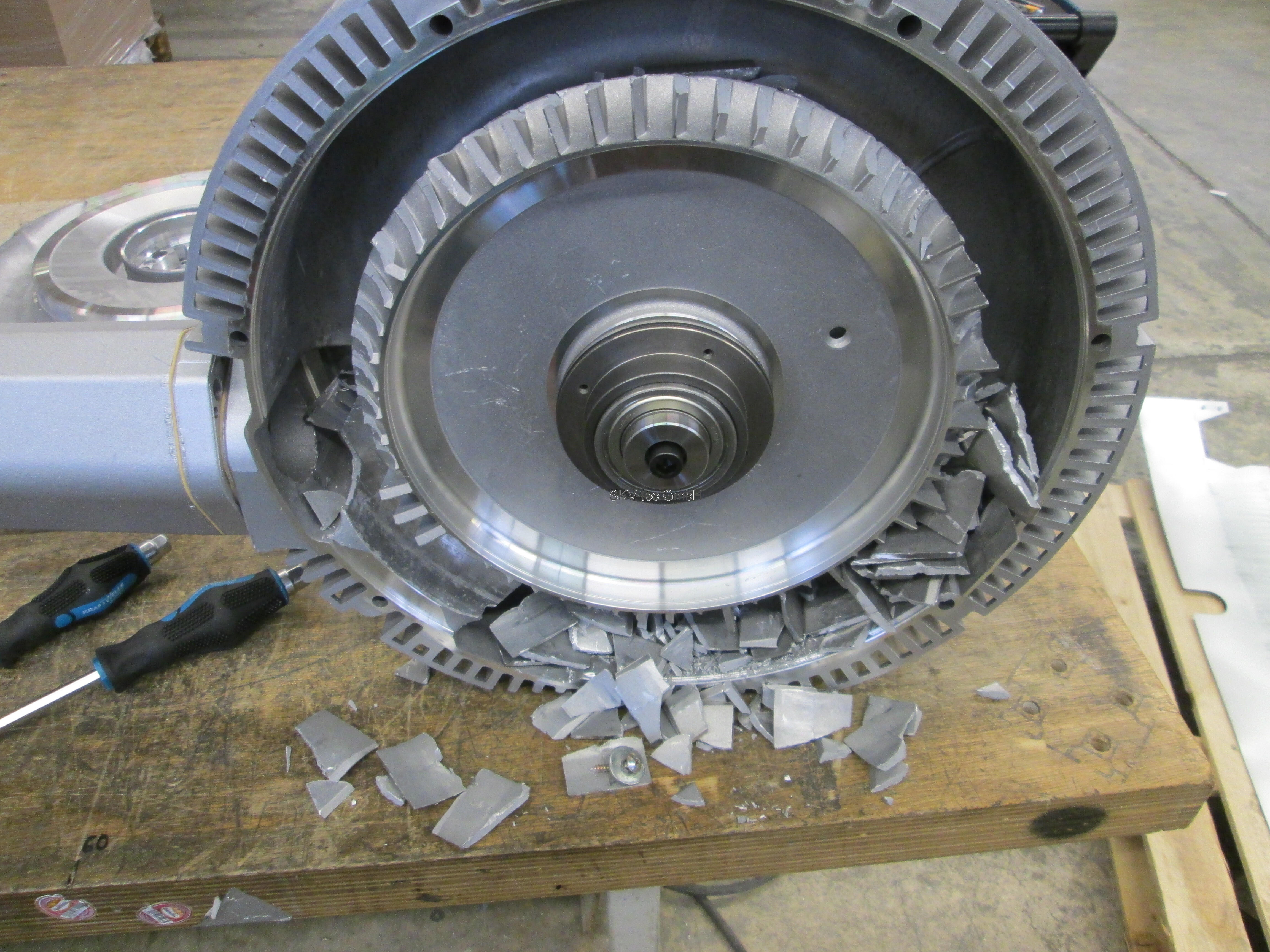

Particles in the air will continually damage the blower, larger object will destroy it immediately.

For small blowers with few working hours, it may be economically feasible to risk it, but after a certain size there can be no argument for running the blower without filter.

Please take special care during a possible trial run of the blower without a filter to avoid sucking in objects.

A few times we have found screws from the foot of the blower in the debris of the impeller.

Please note that the radial velocity of the impellers is very high.

Dirt hits the impeller almost at the speed of sound and can create visible craters in the impeller.

Do the single-phase models work with a variable speed drive?

Our single-phase models are equipped with condensator motors.

The auxillary winding, which is necessary for the start-up momentum, is shifted by 90° to the main winding.

Through the condensator the power supply for this winding is phase shifted by 90°.

In general this kind of motor is not suitable for variable speed drives.

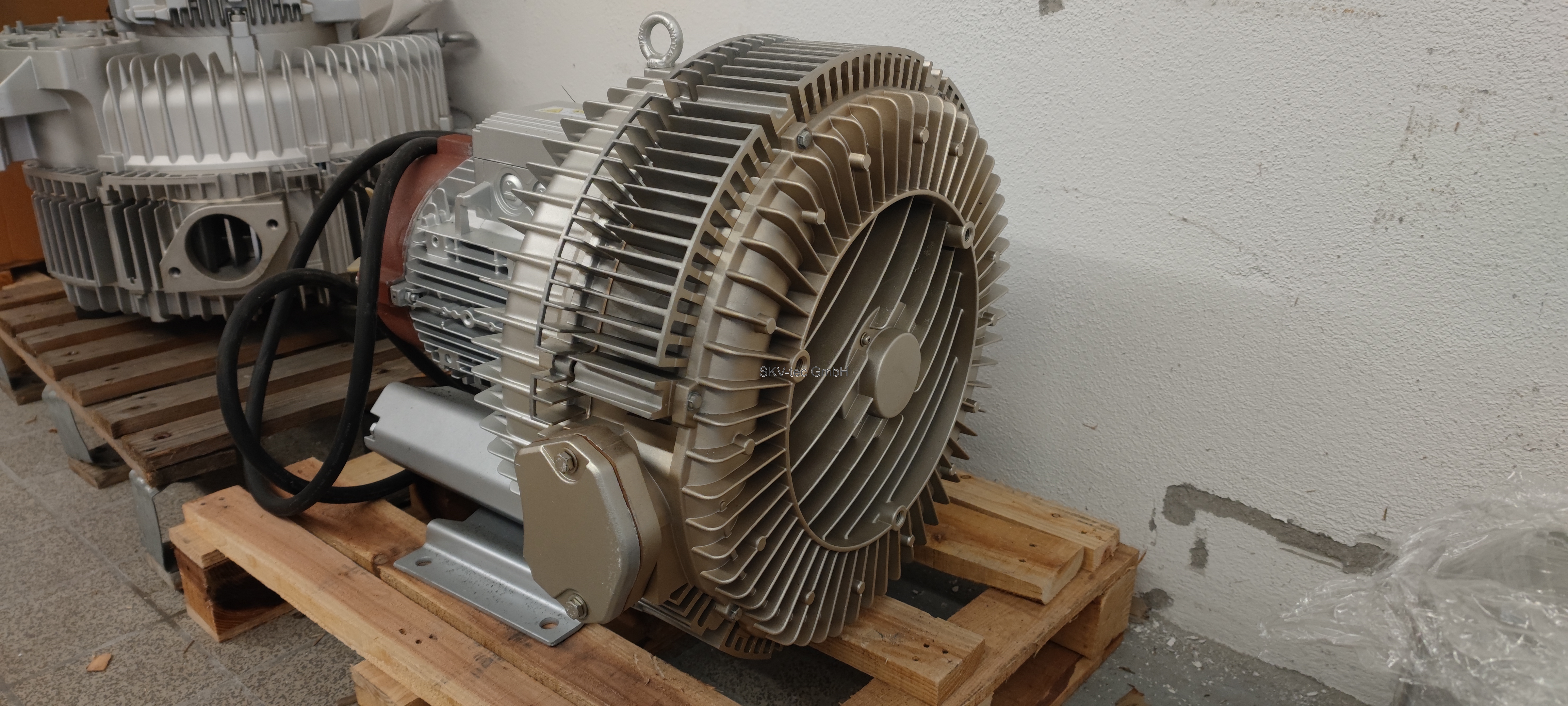

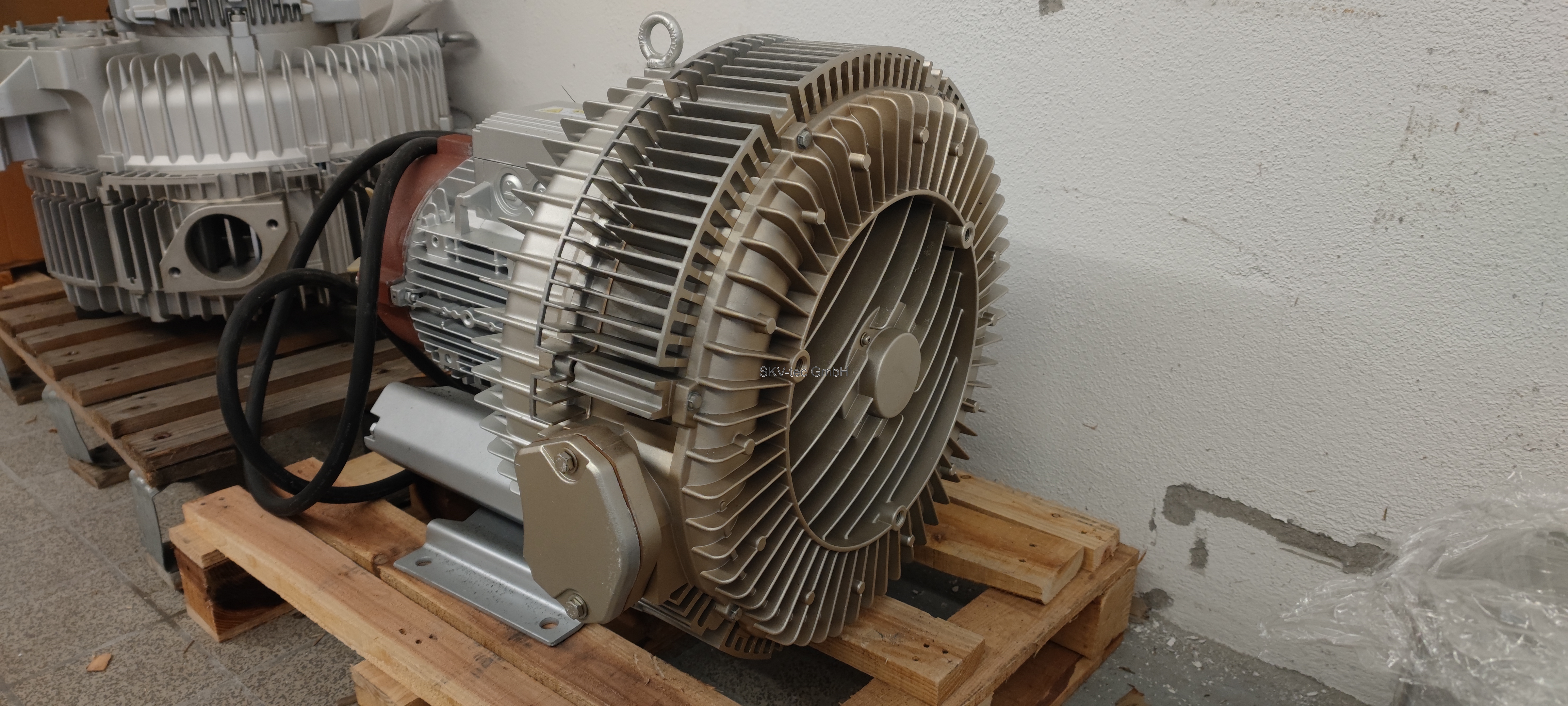

Can your side channel blower be operated outside?

Our blowers are, following their class of protected, relatively well protected against the elements.

We still discourage the unprotected setup of our blowers outside.

Typical problems are the aspiration of very humid air or even rainwater and additional heating by the sun.

Why are you not offering sound insulation hoods?

In general we are critical of sound insulation hoods.

First of all, they need to be designed with the proper spacing and sufficient cooling to avoid damage to the blower.

Our blowers are rather silent, only if the exhaust air directly exits the blower, will the noise exceed the limits.

Unfortunately we know examples, where problems were not noticable due to the sound insulation, causing worse damage in the progress.

Why are you not offering variable speed drives for 230V?

We expect our customers to connect these to normal home sockets, without the proper protection, which is required for their use.

This would cause safety risks in a normal home, for which we do not want to be responsible.

Can I use a safety valve to regulate the pressure?

We offer safety valves, not control valves

Safety valves are not intended to open regularly during normal operations, just due to a rare error.

The design of the valves was made accordingly: the guidance of the valve plate is aluminium against aluminium, which causes high wear

Can I change the exhaust of a double-stage model and use the exhaust below the motor instead?

No!

All our blowers are built in a modular way. Some models only differ from other models by very few parts.

The difference between our single-stage normal pressure models and their double-stage counter-parts is just the additional middle part, the second impeller and the longer shaft.

Therefore our double-stage models also have the connection for the exhaust of the single-stage models, which is covered by a blind.

These blinds are never changed! If you were to use this exhaust and close the second stage exhaust, you stop the cooling of the bearing in the blower and also cause maximum compression and therefore heat in the second stage.

The result is a total loss within a very short time.

Are you also offering other brands than SKV-tec?

We are only offering comparable models to the brands from our comparative tables, but not original models of other brands.

Can I send in my blower for repairs?

We are not a repair workshop. We can conduct repairs, but dedicated repair workshops are better.

Dedicated eletric motor repair shops have more expertise and will also do the work faster.

Therefore we strongly recommend to use the services of these specialists.

Can multi-stage blowers switch the stages?

No!

This question originates from a basic misunderstanding of the working of the stages of a side channel blower.

A single stage blower compresses the air along the scope of the single impeller.

In a double stage blower, after the compression in the first stage, the air flows to the next impeller, the second stage.

There the compression continues, which causes a higher possible pressure and higher air flow due to a reduced backflow in the side channel.

It is merely a mechanical change in built.

The speed of the blower can not be changed.

What do I need to keep in mind, when doing the electrical connection to the connection board?

When connecting single-phase 230V models, the connection board never has to be changed.

The electrical connection is done according to the graphic in the cover of the connection box.

Our three-phase models, not depending on the motor, are always wired for 400V.

Therefore they can be directly connected to the power grid, without any changes.

Please check the limits of your power supplier for direct start of electric motors first.

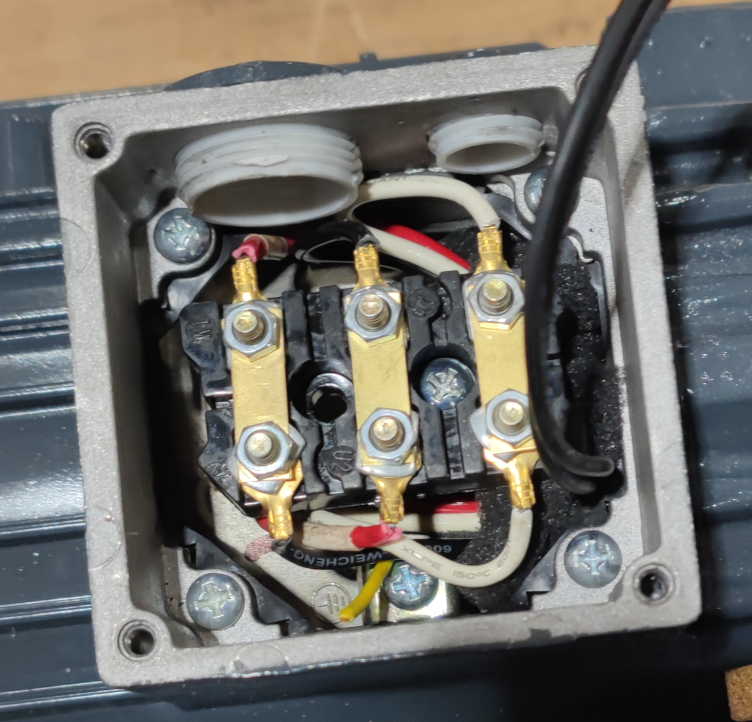

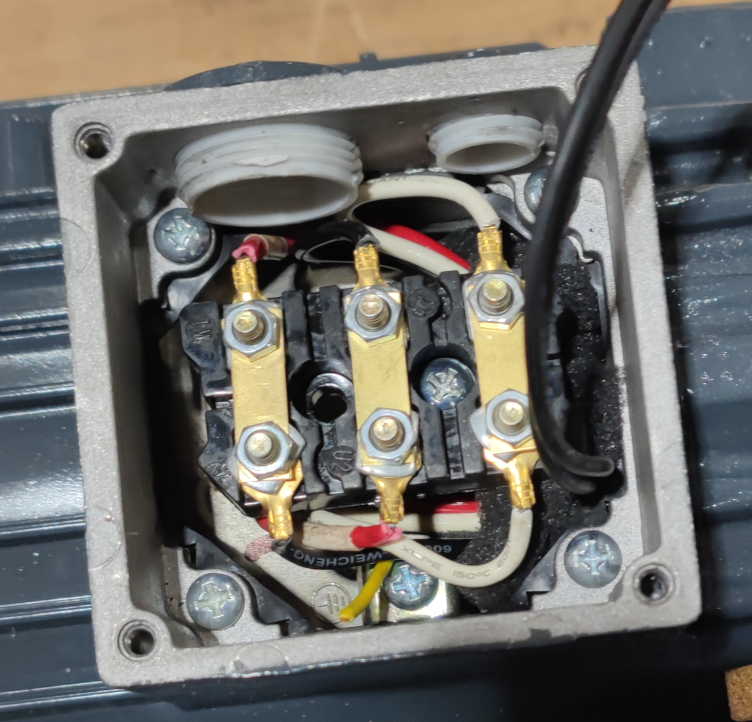

When 230/400V models are prepared for variable speed operations with power increase or 400/690V models are prepared for star-triangle start-up, the copper bridges in the connection box need to be changed/removed.

Remove the screw nuts of the connection board without electrical or hydraulical tools.

When using these tools, sometimes the connection board gets broken, when a screw is ripped out.

Please note the wiring at the connection board, before the removal.

Especially tiresome are mistakes that will cause the motor to work normally when wired at 400V, but short circuit a winding at 230V.

In the picture you can see that the white wire is connected to both ends of one bridge.

What kind of errors can be caused by fault currents in a side channel blower?

Frequency converters, which do not create a pure sinus wave output, always create fault currents and induce a voltage in the shaft of the blower.

The shaft is electrically disconnected from the housing by the shaft seal and bearing grease.

Fault currents can be large enough to cause such a high voltage difference, which is discharged through the bearing grease. This causes erosion and heat in the bearing.

This damage to the bearing is audible like other bearing damages, but can be clearly differentiated visually. You do not need to open the bearing to see the traces of the discharges.

We recommend and build, variable speed drives directly on top of the connection box of the blower in order to limit the cable length.

When a detached variable speed drive is used, the use of a shielded cable is mandatory.

Typically only blowers have problems with currents in the bearings, when a FI type B with 300 mA limit is used.

Where can I find the CE declaration of conformity for the side channel blowers?

You can find our CE declaration of conformity on the second to last page of the operating manual.

The bolts on the shaft of my blower have broken off, do I need a replacement?

No, the bolts are shortened to balance the shaft.

Unfortunately, they are always combinations of cut and break and therefore appear unclean.

What is the significance of blowers with motor identification -3-Px6?

Our side channel blowers with IE2 motors have so-called wide voltage motors and can therefore be operated in almost all combinations of voltage and mains frequency found worldwide.

Our standard IE3 motors -3-7x6, on the other hand, have significantly narrower voltage ranges and therefore cannot be operated in some networks.

The solution to this problem is provided by the Px6 motors, which are wound for 200/230/400V.

The disadvantage is the more complicated terminal board with 9 contacts and 12 wires instead of 6 each.

These motors are also wired to 400V as standard, and for 230V (e.g. frequency converter operation), only the bridges need to be moved.

Based on this consideration, we have decided to stock the -3-Px6 motors.

The -3-7x6 motors, like other special voltages, are available as special orders.